Plate heat exchanger repair/cleaning

Cleaning method for scaling of plate heat exchanger:

1, The choice of cleaning agent

The choice of cleaning agent, currently used for pickling, includes organic and inorganic acids. The main organic acids are: oxalic acid, formic acid and the like. The main inorganic acids are: hydrochloric acid, nitric acid and the like. According to the heat exchanger fouling and process, material and scale composition analysis:

1) The heat exchanger has a small flow area and a complicated internal structure, and it is difficult to discharge if the cleaning liquid is precipitated.

2) The material of the heat exchanger is nickel-titanium alloy, and hydrochloric acid is used as the cleaning liquid, which is easy to produce strong corrosion to the plate and shorten the service life of the heat exchanger.

Through trial and error, it was found that the choice of formic acid as a cleaning solution works well. The buffering agent and the surfactant are added to the formic acid cleaning solution, the cleaning effect is good, and the corrosion of the cleaning liquid on the plate can be reduced. Chemical tests on scale samples have shown that formic acid is effective in removing scale. Through the acid immersion test, it was found that formic acid can effectively remove the scale attached to the sheet, and at the same time it has less corrosive effect on the heat exchanger sheet.

2, The basic principle of removing scale

1) Dissolution: The acid solution easily reacts with calcium, magnesium, and carbonate scale to form a soluble compound, which dissolves the scale.

2) Peeling action: The acid solution can dissolve the oxide on the metal surface and destroy the combination with scale. Thereby, the scale adhering to the surface of the metal oxide is peeled off. And fell off.

3) Air enthalpy action: After the acid solution reacts with calcium, magnesium and carbonate scale, a large amount of carbon dioxide is generated. Carbon dioxide gas is in the process of overflow. For the scale layer which is difficult to dissolve or dissolve slowly, it has a certain enthalpy power, so that the scale falls off from the heated surface of the heat exchanger.

4) Loose effect: For the mixed scale containing silicate and sulfate, since the oxides of calcium, magnesium, carbonate and iron are dissolved in the acid solution, the residual scale becomes loose and the acid solution is easily flowed. Washed down.

3, Process requirements for cleaning scale

1) Pickling temperature: Increasing the pickling temperature is beneficial to improve the descaling effect. If the temperature is too high, it will aggravate the corrosion of the acid heat treatment plate by the acid washing liquid. Through repeated tests, the pickling temperature is controlled at 60~E. should.

2) Pickling solution concentration: According to repeated tests, the pickling solution should be prepared according to the concentration of formic acid 81.0%, water 17.0%, buffer 1.2%, surfactant 0.8%, and the cleaning effect is good.

3) Pickling method and time: The pickling method should be carried out by a combination of static soaking and dynamic circulation. The pickling time is first static soaking for 2 h, then dynamic cycling for 3 to 4 h. The pickling concentration should be sampled frequently during the pickling process. When the difference between the two adjacent assays is less than 0.2%, the pickling reaction is considered to be complete.

4) Passivation treatment: After the acid washing is finished, most of the scale and metal oxide on the surface of the plate heat exchanger are dissolved and detached, exposing a new metal and easily corroding, so after pickling, the heat exchanger plate Passivation treatment.

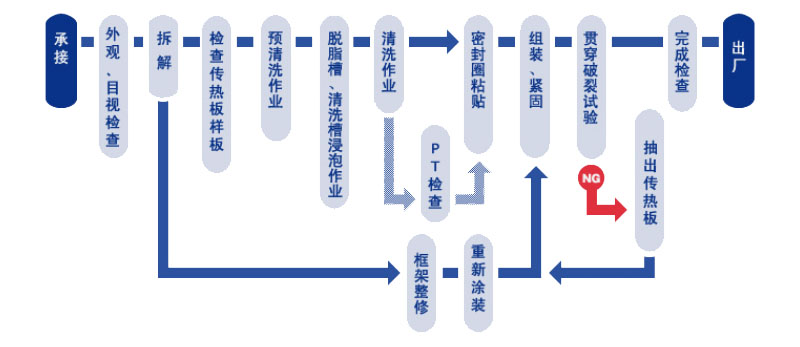

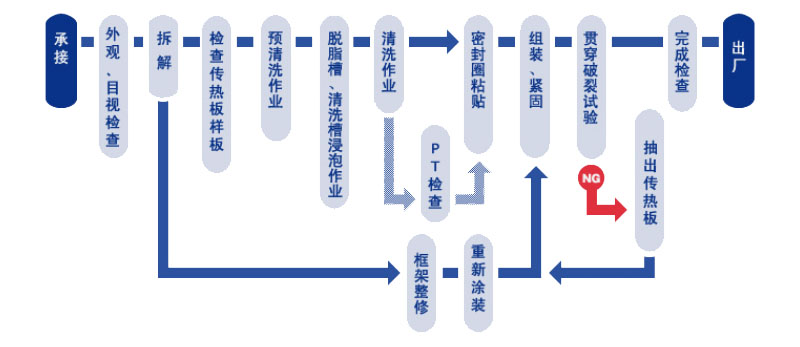

4, The specific steps to clean scale

1) Washing: Before pickling, first open the flushing of the heat exchanger so that there are no impurities such as mud and scale inside the heat exchanger, which can not only improve the pickling effect, but also reduce the acid consumption of pickling.

2) Pour the cleaning solution into the cleaning equipment and then inject it into the heat exchanger.

3) Pickling: The heat exchanger filled with the acid solution was statically soaked for 2 h. Then continuously cycle for 3 to 4 hours. The positive and negative alternate cleaning is performed every 0.5h. After the acid washing is finished, if the pH of the acid solution is greater than 2, the acid solution can be reused. Otherwise, the acid washing solution should be diluted and neutralized and drained.

4) Alkaline washing: After the acid washing is finished, NaOH, Na, PO and demineralized water are prepared in a certain ratio, and the heat exchanger is subjected to alkaline washing by means of dynamic circulation to achieve acid-base neutralization and heat exchanger plate. The piece no longer corrodes.

5) Washing: After the alkali washing is finished, the heat exchanger is repeatedly rinsed with clean softened water for 0.5 h, and the residue in the heat exchanger is thoroughly rinsed.

6) Recording: During the cleaning process, the time of each step should be strictly recorded to check the cleaning effect. In short, after the cleaning is completed, the heat exchanger is subjected to a compression test. It can be used after passing the test.

5, Measures to prevent scaling of plate heat exchangers

1) Strictly control the water quality during operation, and carry out strict water quality tests on the water in the system and the softened water in the softening tank. After passing the test, it can be injected into the pipe network.

2) When the new system is put into operation, the heat exchanger should be separated from the system. After a period of cycle, the heat exchanger should be incorporated into the system to avoid impurities entering the heat exchanger in the pipe network.

3) In the whole system, the decontamination device and the filter should be cleaned occasionally, and the pipe network should be kept clean to prevent the heat exchanger from being clogged.

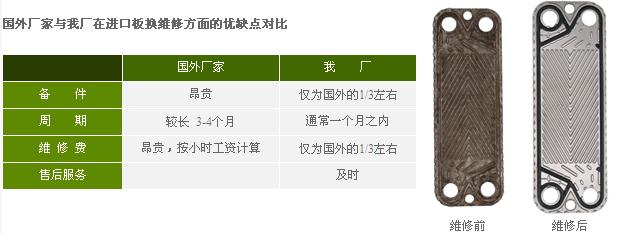

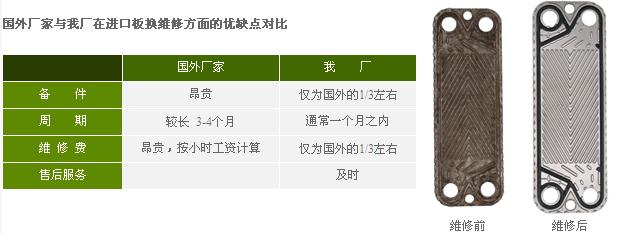

Over the years, our factory has built a factory for many years, with its own ability to mold, coupled with the good conditions of rubber pad production, has provided maintenance services for hundreds of domestic imported plate users. Simply transfer the old version to our factory and we will provide you with the service.

Multi-Brand spare parts (plates / gaskets)

The company has its own heat exchanger sheet and gasket factory in China, offering world-renowned brands (brands include: SPX/SPX, Ampere/APV, GEA/GEA, TRANS/ARD, Sanders) /SONDEX, Eppel Schmidt/API.Schmidt, Fengkai/FUNKE, Samoweifu/Thermowave, Vikpo Vicarb, Donghe Entai/DONGHWA, Axon ACCESSEN, MULLER, FISCHER, REHEAT, etc. The detachable plate heat exchanger replaces the plates and gaskets, and has nearly a thousand models, which is an alternative to the brand plate heat exchanger accessories. Plate heat exchanger customers in different countries and industries around the world are using our heat exchanger accessories and are working well.

Multi-Brand maintenance service

— OEM value

Regardless of the brand of plate heat exchanger installed in your facility, the performance on the OEM nameplate can be achieved. Our service center wants to ensure that you continue to enjoy the performance noted on the nameplate. With our fast, economical and reliable service, your heat exchangers can achieve low downtime and reliable maintenance.

To this end, we offer OEM-quality spare parts and services for every plate heat exchanger you use, including APV Ampere, SPX, Kelvion, GEA GEA, ARD, Sondex Dess, Danfoss Danfoss, Vicarb Vikpo, Funke Winds, Thermowave Samo Weifu plate heat exchangers, and all equipment will be able to enjoy genuine spare parts and services.

For heat exchangers, you get a lot of service. We track the original design conditions based on the serial number on the heat exchanger nameplate you are using to confirm that the product information is authorized.

For faulty equipment:

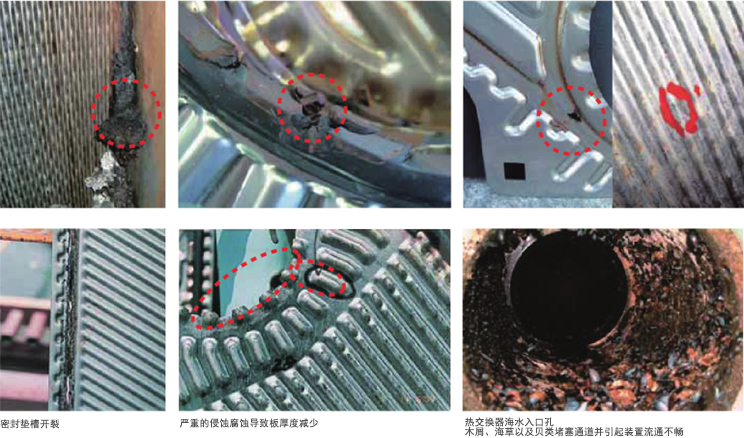

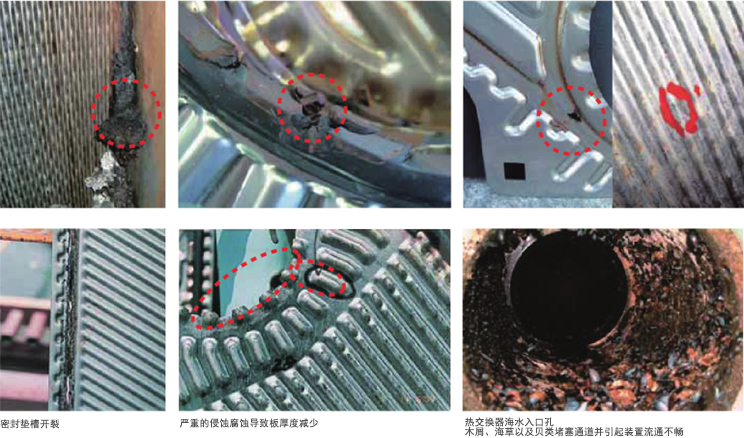

We will check your current operation to understand the cause of deterioration, expansion or cracking of the gasket and then replace the gasket

We will provide the correct bonding method, replacing the cracked and leaking gasket with a new gasket.

We will provide the correct sealing practices to prevent over-tightening and damage to the plates.

With an authorized service outlet, you always have access to the right gaskets and plates as well as friendly service and our OEM guarantee.

— Field Service

The service center's field service personnel can restore your plate heat exchanger to the nameplate at any time. Whether it's a planned downtime or emergency service, OEM spare parts and services will benefit your heat exchanger. The service center relies on Erede's global engineering resources (including design, application and materials engineering) to successfully complete tasks. New spare parts used in all our on-site work will be covered by a one-year warranty and include process and labor costs.

On-site services include:

• Renovation of the bundle (open and assemble the heat exchanger, pressure clean the plate, visually inspect the plate, inspect the gasket and replace as needed)

• Slab exchange

• Water pressure / pipeline testing of heat exchangers

• Troubleshooting

• Send pick-up (for work that needs to be done at our factory)

Our personnel can also provide cleaning services for most brands of welded plate heat exchangers other than Ered products. If the channel is accessible, pressure cleaning is usually used to remove most of the contaminants.

Technical service personnel are certified by the relevant country.

— On-site maintenance and return to factory maintenance

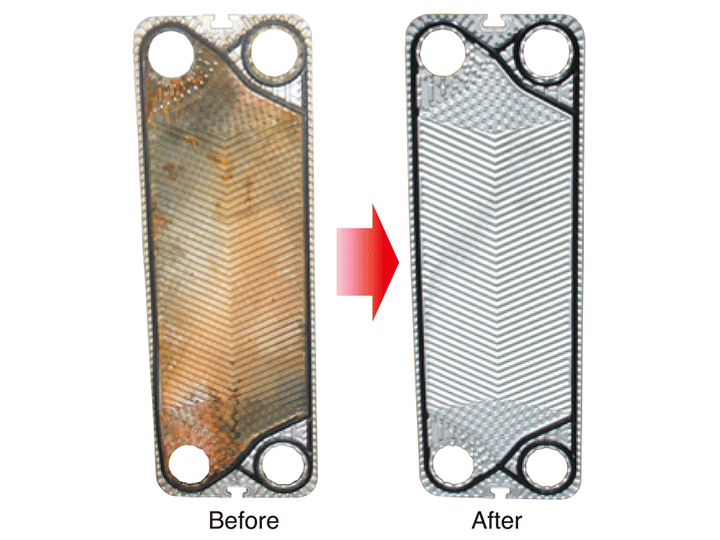

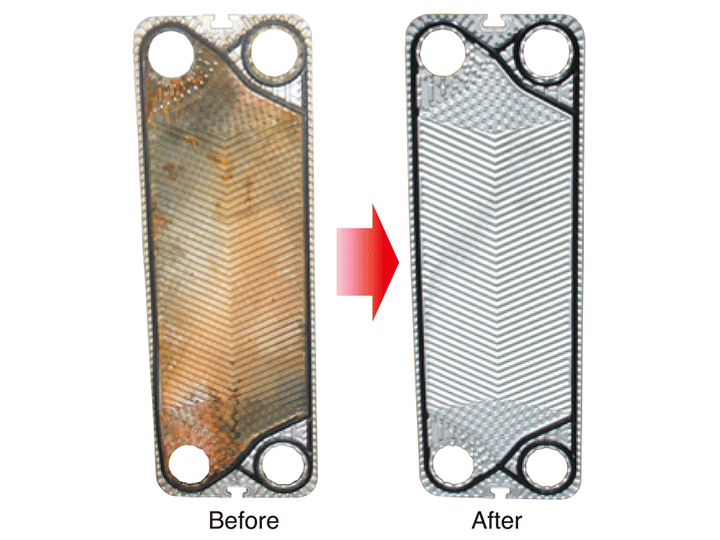

Although the plate heat exchanger is durable, after long-term use, it is difficult to maintain the original performance due to deterioration of the seal ring, adhesion of the stain, and the like, and various problems such as liquid leakage may occur. In order to make the plate heat exchanger usable in a long-term, stable, and good condition, regular maintenance is indispensable.

While ensuring the inventory of various replacement parts such as seals, we also provide a wide range of services according to the needs of our customers. For example, dispatching skilled technicians to carry out on-site maintenance and “recovering factory inspection and renovation” Service" and so on.

The company has accumulated a wealth of technical experience and has spread advanced heat transfer plate technology to the world. In this way, we can provide "reliable" and "trusted" maintenance services.

|

|

If you do not pay attention to maintenance for a long time...

PRODUCTS

PRODUCTS SOLUTIONS

SOLUTIONS